> 91%

recycling rate

2.500 MWh

green energy

DIN EN ISO 14001

environment certification

seele takes responsibility – our goal: net zero

In the transformation to carbon neutrality, the construction sector is a key industry. As an industrial company, we have a special responsibility because we use raw materials to build unique façades. Our goal is to use scarce resources as efficiently as possible. To this end, we obtain energy from renewable sources, manage raw materials responsibly and take steps to ensure the longevity of our products.

As an owner-managed company, we can make quick decisions and take swift action. We don’t simply talk about sustainability, we shape it. We are working intensively to reduce our carbon footprint. Similarly, we assume responsibility for supporting our customers in achieving their sustainability goals. We are moving intently along the route to net zero. By when? Better today than tomorrow.

Our areas of action:

- Renewable energy

- Reducing and recycling waste

- Reporting and transparency

- Raising awareness

- Recommendations and life cycle assessment

seele's fact check on sustainability

Renewable energy – with high investments

There is no question that the transition to climate neutrality needs clever concepts and lots of money. As an owner-managed company, we have the advantage of being able to make decisions quickly and to apply the necessary financial resources. In the past, we focused primarily on saving energy. Now we are focusing on generating it. We produce our own electricity and save 136 metric tons of CO2. We are also working on concepts for heat recovery. And we supplement whatever electricity we cannot produce ourselves by purchasing it from renewable energy sources. We establish precedents that are measurable. Our goal: shift to 100% renewable energy.

Reducing and recycling waste – prevention make economic sense

When it comes to waste, too, the goal is prevention and to return valuable raw materials to the circular economy. With the steady reduction of waste and a recycling rate of over 90%, we are on the right track. We scrutinise every process and optimise what is possible: we avoid surplus deliveries, utilise modern tracking methods and nesting software, convert packaging materials, replace hazardous materials, and save paper by using digital processes. Our goal: To improve measurably every year (waste report).

Reporting and transparency – basics for agile sustainability management

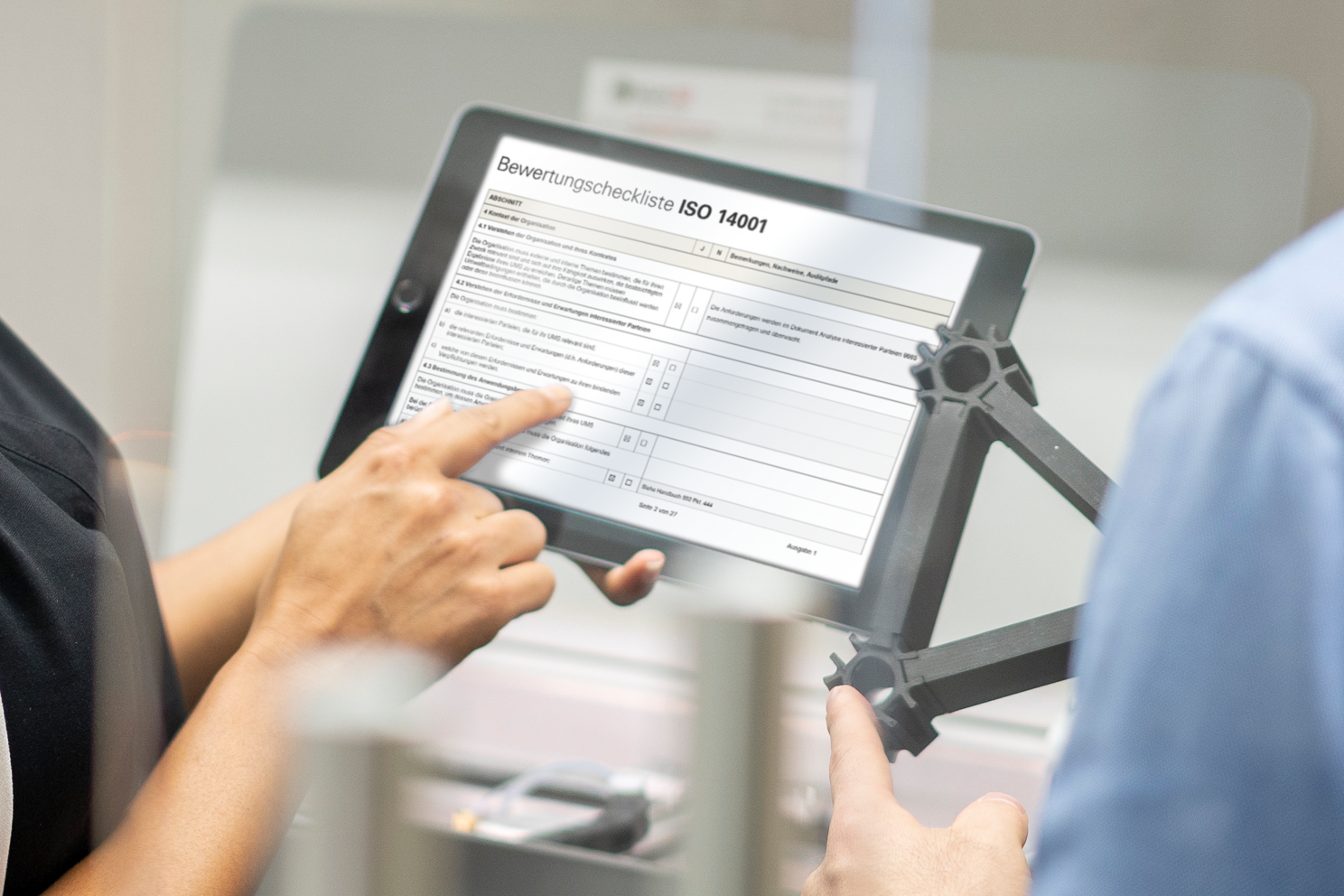

Our modern building management system records consumption so we can act in line with performance indicators. Monitoring of the production machinery is also very important in order to optimise the control system and to detect possible leaks. The analyses are incorporated into our life cycle assessments and our DIN EN ISO 14001:2015 (environment) and DIN EN ISO 50001:2018 (energy) certifications. We don’t simply talk about necessary changes, we implement them in our environmental and energy action plans. Our goal: Detailed monitoring of all consumption by 2025.

Raising awareness – together we succeed

We attach great importance to raising our employees’ awareness and training them. To this end, we regularly organise environment weeks and informational events.

Our specialised in-house departments are actively involved in national and international professional associations in efforts to solve the major issues together with other experts. We have also incorporated sustainability issues as an integral component of our audits of subcontractors and suppliers. We are in the process of actively shaping the industry as it transforms. Our goal: sustainability monitoring of suppliers at 100% by 2025.

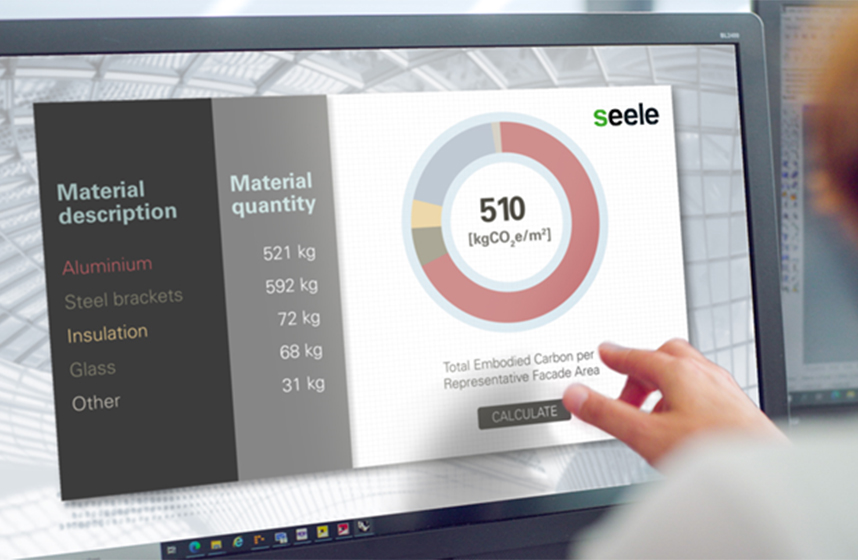

Recommendations and life cycle assessment – form follows sustainability

Maximising the minimum – saving resources is our utmost priority. We provide our customers with advice even in the quotation phase, and with sero, our CO2 calculator, we reveal possibilities for optimisation. Less is more – especially in the use of materials. We take care at the design stage to use materials in ways that keep them as homogeneous as possible, so the raw materials can be recycled at a high rate when the product reaches the end of its life cycle. We already maintain detailed material registers for many construction projects. But between production and recycling lies the service life, and in this longest period we offer building users outstanding maintenance of the building envelope. Our goal: Provide a material passport for our project to 100% by 2024.